In recent years, the advancements in laser technology have significantly transformed the manufacturing landscape, particularly in the domain of metalworking. A key player in this transformation is the Laser Pipe Cutting Machine, which has emerged as an indispensable tool for industries requiring precision cutting and enhanced efficiency. According to a report by MarketsandMarkets, the global laser cutting market is projected to reach $6.78 billion by 2025, driven by increased demand for high-quality cuts and reduced operational costs. Innovations in laser pipe cutting machines not only improve the accuracy and speed of cutting processes but also contribute to minimizing waste and maximizing material utilization. This article explores ten groundbreaking innovations in Laser Pipe Cutting Machines that you should know, which are poised to redefine productivity standards across various sectors.

Recent advancements in laser pipe cutting technology have transformed the industrial landscape, offering enhanced precision and efficiency over traditional cutting methods. Innovative laser systems utilize advanced optics and intelligent software, enabling operators to achieve intricate cuts and complex geometries with minimal material waste. The integration of automation and robotics into laser cutting processes further streamlines production, reducing downtime and increasing overall throughput.

Moreover, the development of fiber laser technology has significantly improved cutting speed and energy efficiency. These lasers have a higher power density, facilitating faster cuts even on thicker materials. As manufacturers increasingly adopt eco-friendly practices, laser cutting systems that reduce emissions and conserve energy are becoming a priority. Additionally, the trend towards customization and adaptation in manufacturing has led to the creation of modular laser cutting machines, allowing facilities to scale their operations according to project demands seamlessly. The ongoing evolution of laser pipe cutting technology signifies a promising future for the manufacturing sector, emphasizing sustainability and enhanced performance.

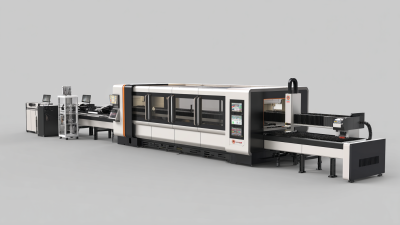

Modern laser pipe cutting machines have revolutionized metal fabrication with their advanced features that enhance efficiency and precision. One of the key attributes is the integration of fiber laser technology, which offers superior cutting speeds and reduced operational costs. This technology provides a high-quality cut finish and requires minimal maintenance, making it a preferred choice for industries that demand high productivity.

Another significant feature is the implementation of automated loading and unloading systems. These systems streamline the workflow, reducing manual labor and minimizing downtimes. Coupled with advanced software solutions for programming and monitoring, operators can optimize the cutting process, ensuring that even complex designs are executed flawlessly. Additionally, many modern machines are equipped with intelligent software that can auto-adjust parameters based on material type and thickness, further enhancing the versatility and ease of use in various applications.

In the world of manufacturing, laser pipe cutting technology has seen remarkable innovations that enhance efficiency and precision. Recent comparative analyses across various manufacturing technologies, such as micro-milling, metal 3D printing, etching, and laser cutting, have shed light on the effectiveness of laser cutting in producing intricate designs with minimal material waste. A study revealed that laser cutting provides superior edge quality and process speed, particularly for complex shapes in materials like stainless steel, which is critical for industries where precision is paramount.

Moreover, advancements in laser technology are driving a shift towards automation and integration in manufacturing processes. Laser cutting machines equipped with advanced software can now optimize cutting paths and reduce cycle times significantly. Reports indicate that the global laser cutting market is expected to reach a valuation of over $5 billion by 2027, underscoring the growing reliance on this technology. With the ability to process various materials and thicknesses, innovations in laser pipe cutting are transforming production lines, making them more adaptable and efficient in meeting consumer demands.

The impact of laser pipe cutting on manufacturing efficiency is profound, as these innovations streamline production processes and enhance precision. Traditional cutting methods often involve significant time and material waste, whereas laser cutting technology significantly reduces these inefficiencies. With the capability to cut through various materials with remarkable speed and accuracy, manufacturers can achieve tighter tolerances and complex designs that were previously difficult or impossible to produce.

Furthermore, the adaptability of laser pipe cutting machines allows for quick changes in production runs, responding swiftly to customer demands and market fluctuations. This agility not only increases productivity but also helps reduce operational costs. As a result, manufacturers benefit from higher output and lower scrap rates, which ultimately translates into improved profit margins. The integration of advanced laser cutting technologies represents a shifting paradigm in manufacturing, enabling companies to achieve more with less while maintaining high standards of quality and craftsmanship.

The advancement of laser pipe cutting machines is witnessing remarkable innovations that pave the way for future industry trends. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to reach USD 5.67 billion by 2026, growing at a CAGR of 6.8% from 2021. This surge is primarily driven by the increasing demand for precision cutting and the rise in automation across various industries, including aerospace, automotive, and manufacturing. The future of laser cutting technology is leaning towards higher efficiency, with developments in fiber laser technology leading to faster cutting speeds and lower operational costs.

Another significant trend is the integration of artificial intelligence and machine learning into laser cutting systems. These technologies enable predictive maintenance and optimize cutting parameters in real-time, significantly improving productivity. A study conducted by Research and Markets highlighted that the implementation of AI solutions could boost machine efficiency by up to 20%. Furthermore, the rise of smart factories and Industry 4.0 concepts is pushing manufacturers to adopt more intelligent and connected laser cutting machines, enhancing overall process visibility and control, thus solidifying the role of laser technology in modern manufacturing landscapes.