In today's fast-paced manufacturing landscape, selecting the right Laser Cutting Machine is critical for businesses aiming to enhance productivity and maintain competitive advantage. According to a report by Allied Market Research, the global laser cutting machine market was valued at $3.2 billion in 2020 and is projected to reach $5.6 billion by 2027, growing at a CAGR of 8.5%. This growth is driven by the increasing demand for precision and efficiency in various industries, including automotive, aerospace, and metal fabrication. As more companies adopt advanced manufacturing technologies, understanding the fundamental aspects of laser cutting machines, such as their capabilities, materials compatibility, and cost-effectiveness, is essential for making informed decisions that align with specific business needs. This guide aims to equip you with the knowledge necessary to choose the perfect laser cutting solution tailored to your operational requirements.

When selecting the right laser cutting machine for your business, it is crucial to understand the specific requirements of your operations. The laser cutting market is expanding significantly, with projections indicating that the market size will reach approximately 368.5 billion yuan by 2024. This growth is driven by the increasing demand for advanced manufacturing technologies across various industries, highlighting the importance of investing in machinery that aligns with your production needs.

The diverse applications of laser cutting technology further underscore the necessity of tailoring your choice to your business's unique requirements. Whether you are focusing on precision cutting for intricate designs or high-speed operations for large-volume production, understanding the capabilities of different laser cutting machines will enable you to make an informed decision. Reports suggest that the adoption of laser processing equipment is steadily increasing, particularly in sectors capitalizing on innovations in smart manufacturing, which utilize laser technology for efficiency and accuracy. Thus, aligning your machinery selection with industry trends and your operational goals is essential for sustaining competitiveness in a rapidly evolving market.

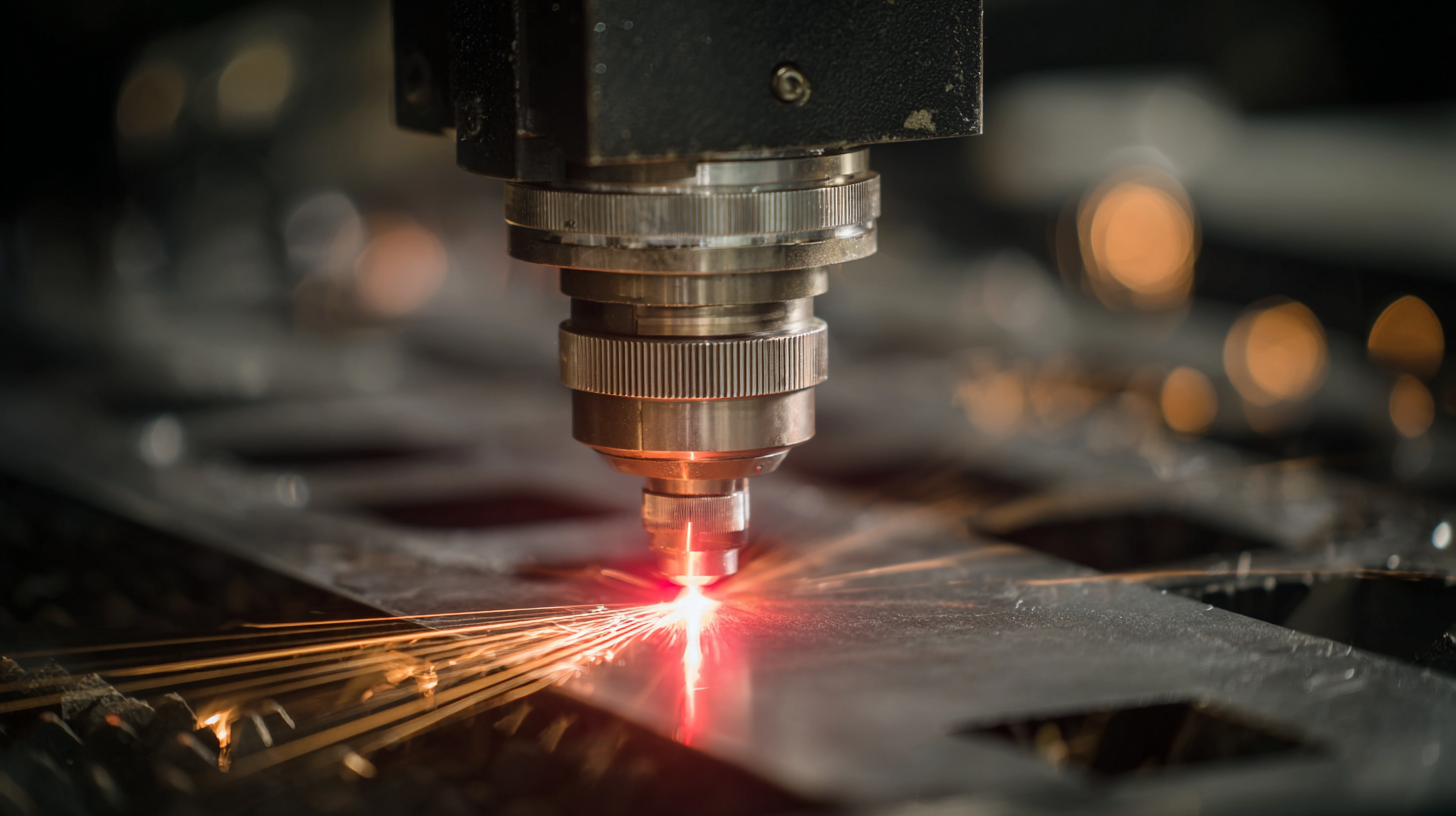

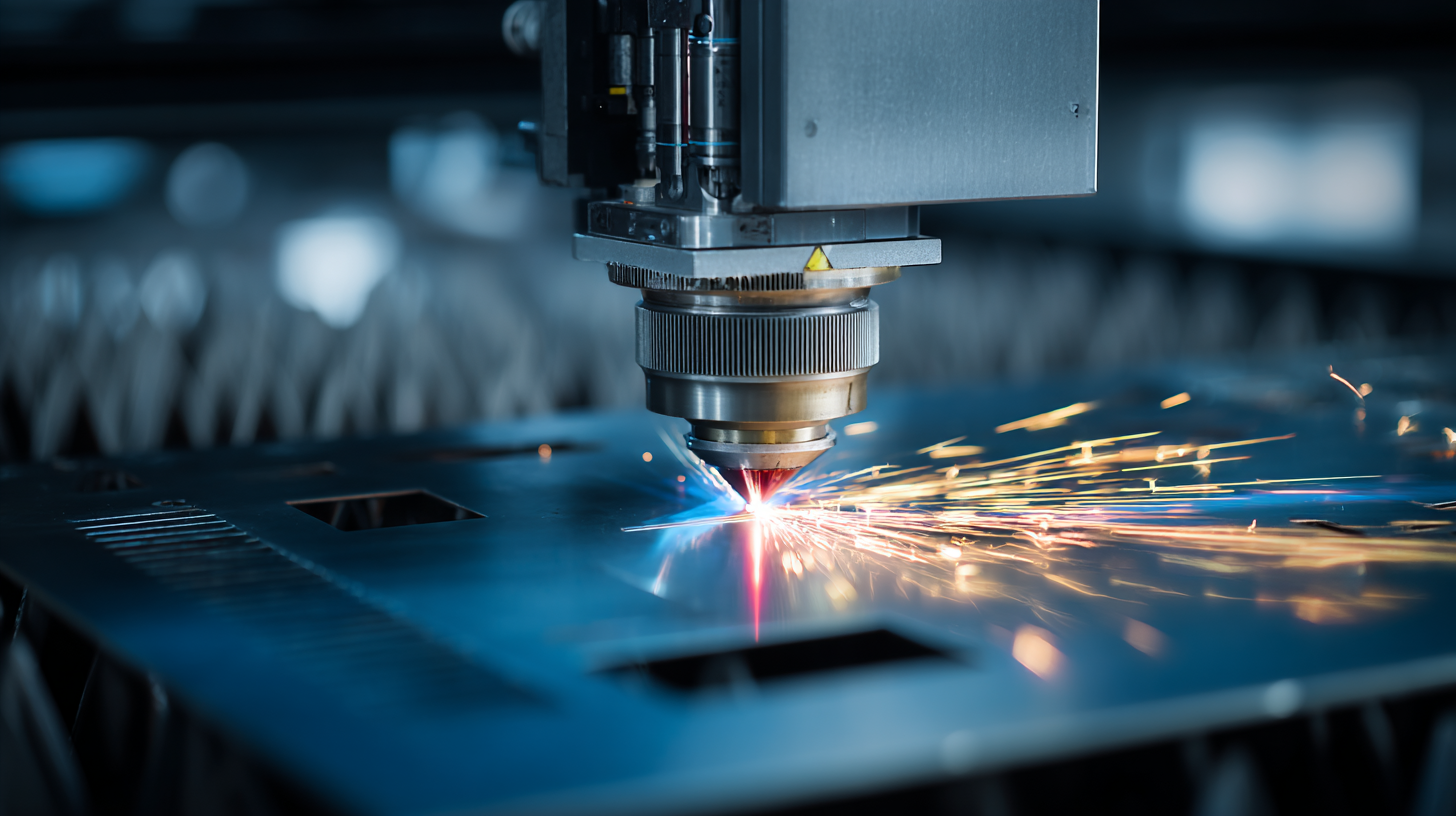

When it comes to selecting the right laser cutting machine for your business, understanding the different types available is crucial. Whether you are cutting metal, wood, acrylic, or fabric, the technology behind laser cutting can vary significantly.

CO2 laser cutters are a popular choice for non-metal materials, such as wood and plastics, due to their efficiency and precision. They provide smooth finishes and intricate designs, making them ideal for signage and detailed artwork.

CO2 laser cutters are a popular choice for non-metal materials, such as wood and plastics, due to their efficiency and precision. They provide smooth finishes and intricate designs, making them ideal for signage and detailed artwork.

On the other hand, fiber laser cutting machines excel in cutting metals, including stainless steel, aluminum, and brass. They offer faster cutting speeds and lower operating costs in the long run, making them a suitable option for high-volume production environments. Additionally, consider your workspace and production needs—some machines are compact and versatile for small workshops, while others may require more space and are geared towards large-scale operations.

Assessing the materials you'll be working with, production speed, and budget will guide you in choosing the right laser cutting machine tailored to your specific business requirements.

When selecting a laser cutting machine for your business, understanding the key features is crucial to ensuring that you make an informed decision. One of the primary factors to consider is the type of laser technology used. CO2 lasers are ideal for cutting non-metal materials like wood, acrylic, and fabric, while fiber lasers excel with metals such as steel and aluminum. Depending on your material requirements, choosing the appropriate laser type will significantly impact your efficiency and output quality.

Another essential feature to evaluate is the cutting area size. Depending on the scale of your operations, you may need a machine with a larger cutting bed to accommodate bigger projects or high-volume production. Additionally, consider the machine's speed and precision; these will affect turnaround times and the overall quality of the final product. Advanced features like autofocus systems and user-friendly software can further enhance productivity and ease of use, making them worth investing in for long-term business growth.

When choosing a laser cutting machine for your business, it's crucial to evaluate the delicate balance between cost and quality. Investing in high-quality machinery can lead to enhanced efficiency and precision, resulting in better end products. However, a high price tag doesn’t always guarantee superior performance. Therefore, conducting thorough research and comparing specifications across different models is essential. Look for features that align with your specific cutting needs, whether that’s speed, material compatibility, or safety protocols, as these can significantly impact your operational costs.

In addition to upfront costs, consider the long-term expenses associated with maintaining and operating the machine. Cheaper options may offer lower initial investments but can lead to higher maintenance and operational costs down the line. Quality machines often come with warranties, customer support, and require fewer repairs, which can save money over time. By carefully weighing these aspects, you can find a machine that not only fits within your budget but also meets your business's quality standards and production goals.

Maintaining and supporting your laser cutting investment is crucial for ensuring long-term efficiency and profitability. Industry reports indicate that regular maintenance can extend the lifespan of a laser cutting machine by up to 40%, significantly reducing the need for costly repairs or replacements. It's essential to develop a systematic maintenance schedule that includes routine inspections and timely replacement of worn parts.

Tip: Always keep the machine's manual on hand for reference, and track maintenance activities meticulously. This practice not only ensures compliance with warranty requirements but also provides valuable insights into the machine's performance over time.

Additionally, investing in staff training can enhance operational efficiency and reduce errors. According to a study by the Fabricators & Manufacturers Association, companies that provide regular training see a 25% increase in productivity on average. Ensuring that your team is well-equipped to handle the laser systems can lead to better quality output and less downtime.

Tip: Consider engaging with the machine manufacturer for training programs or workshops that can keep your team updated with the latest technologies and best practices in laser cutting.