In today's rapidly evolving manufacturing landscape, investing in the right equipment is crucial for staying competitive. The Tube Laser Machine has emerged as a transformative tool, enabling businesses to enhance precision, efficiency, and versatility in tube processing. According to a report from Market Research Future, the tube laser cutting market is projected to grow at a CAGR of 4.5% from 2020 to 2027, demonstrating a robust demand for laser technology. Furthermore, businesses that have adopted tube laser machines report up to a 30% reduction in production time and significant cost savings on material waste, underscoring their effectiveness in streamlining operations. With various models and technologies available, selecting the appropriate Tube Laser Machine tailored to specific business needs can be daunting. This blog aims to provide essential tips and insights to guide decision-makers in making an informed choice, ensuring they harness the full potential of this advanced technology.

When selecting a tube laser machine, several key factors can significantly influence your choice and ensure optimal efficiency for your business. Firstly, understanding the specific materials you will be working with is crucial. Different machines offer varying compatibility with materials such as steel, aluminum, or copper. Additionally, the thickness and diameter of the tubes you plan to process will dictate the laser power and cutting speed required, ensuring you select a machine that meets your production demands without compromising on quality.

When selecting a tube laser machine, several key factors can significantly influence your choice and ensure optimal efficiency for your business. Firstly, understanding the specific materials you will be working with is crucial. Different machines offer varying compatibility with materials such as steel, aluminum, or copper. Additionally, the thickness and diameter of the tubes you plan to process will dictate the laser power and cutting speed required, ensuring you select a machine that meets your production demands without compromising on quality.

Another critical factor to consider is the machine's automation capabilities. An automated tube laser machine can greatly enhance workflow efficiency by reducing manual labor and increasing throughput. Features such as advanced software for nesting and programming can lead to reduced waste and improved material utilization. Moreover, evaluating the machine’s maintenance requirements and available support services is essential for sustaining long-term productivity and minimizing downtime. Investing in a machine with a solid service plan can save considerable time and money in the long run, allowing your business to operate at peak performance.

When selecting a tube laser machine for your business, it’s important to understand the different types available and their specific applications. Tube laser machines can generally be categorized into two types: fiber laser machines and CO2 laser machines. Fiber lasers are known for their efficiency and precision, making them ideal for cutting metals like stainless steel, aluminum, and brass. On the other hand, CO2 lasers excel in cutting non-metal materials such as acrylic, wood, and textiles. Knowing what materials you will predominantly work with is crucial in determining which type of laser machine will best suit your needs.

Tip: Assess your production volume and speed requirements. Fiber lasers tend to have faster cutting speeds, making them suitable for high-volume production environments. Consider the thickness of the materials you frequently use as well; choosing a machine that can handle a variety of thicknesses can provide greater versatility in manufacturing processes.

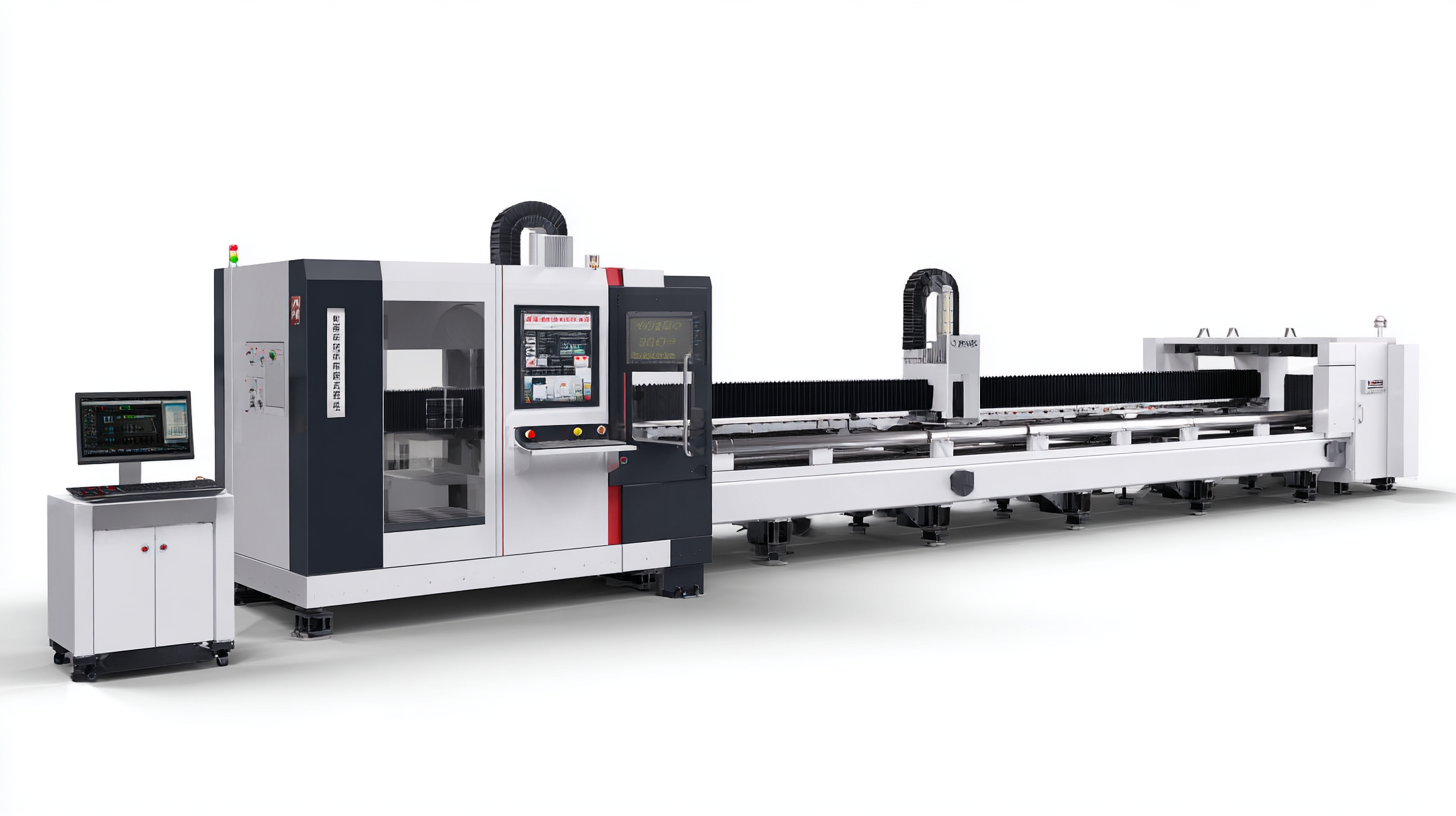

Another important factor to consider is the size of the machine and the workspace you have available. Some tube laser machines are designed for large tubes and can handle more significant workloads, while others are compact and suitable for smaller businesses. Ensure that you choose a machine that fits well within your operational space while still meeting your production demands.

Tip: Evaluate the software compatibility of the tube laser machine with your existing manufacturing systems. An intuitive software interface can significantly enhance productivity and ease of use, enabling your team to adapt quickly and operate the machine efficiently.

Choosing the right tube laser machine involves a thorough evaluation of its key specifications, particularly power output, cutting speed, and beam quality.

Power output influences the material thickness that can be effectively cut. For instance, machines with a power rating of 2 kW are capable of cutting up to 10 mm of mild steel, while 6 kW machines can handle thicker sections. This is crucial in industries where precision cutting of materials like copper is imperative for maximizing edge quality, as noted in recent studies that emphasize optimizing processes for improving performance.

Cutting speed is another pivotal specification. High-speed laser cutting not only enhances productivity but also contributes to reduced thermal distortion, which is vital in applications such as micro-channelling in PMMA. Current research has shown that laser systems can achieve cutting speeds exceeding 20 m/min, offering significant advantages in terms of operational efficiency.

Tip: When assessing cutting speed, consider both the material type and the desired finish, as this may affect your choice of machine. Additionally, the quality of the beam is essential for producing precise cuts; Gaussian beam profiles typically result in smoother edges, which are paramount in high-quality applications.

Tip: It’s also worth investing in machines with adaptability for different materials, as this will allow your business to stay competitive across various markets.

When considering the acquisition of a tube laser machine, a cost-benefit analysis is essential to ensure that your business makes the right financial decision. While the initial investment for high-quality tube lasers can range from $150,000 to over $1 million depending on the complexity and size of the machine, the potential for long-term savings is significant. Industry reports indicate that businesses utilizing tube lasers see up to a 30% reduction in manufacturing time and 20% lower operating costs compared to traditional cutting methods. This efficiency can lead to quicker project turnaround and enhanced profitability.

Tip: When selecting a machine, evaluate your production volume and the variety of materials you'll be cutting. Machines that offer greater versatility might incur a higher upfront cost but will save you from investing in multiple machines over time.

Moreover, tube lasers offer precision that minimizes waste, which further contributes to cost savings. A study by the National Institute of Standards and Technology noted that laser cutting can achieve up to 95% material utilization, directly impacting the bottom line. By factoring in both the precision and speed of tube lasers, companies can balance the initial investment with the long-term benefits of reduced labor costs and improved product quality.

Tip: Don’t forget to include training costs for your staff in the initial investment plan. Proper training can maximize machine utilization and efficiency, ensuring you get the best return on investment.

As industries evolve, the selection of tube laser machines becomes increasingly influenced by emerging technologies and industry trends. One notable trend is the growing concern regarding stern tube damages, which highlights the critical need for precision in manufacturing processes. Damages in stern tube and shafting systems, which can range from minor seal leaks to severe mechanical failures, underscore the importance of investing in high-quality tube laser machines that can deliver accurate cuts and high durability.

Additionally, advancements in laser technology are transforming the capabilities of tube laser machines, allowing businesses to create intricate designs while maintaining efficiency. With the rise of automation and smart manufacturing, it’s essential for companies to consider how these technologies can synergize with their operational requirements. Selecting a tube laser machine equipped with the latest features can not only enhance productivity but also significantly reduce the risk of errors that may lead to costly equipment damages. As you navigate your options, pay close attention to how new technologies in tube laser machines can directly impact your business's reliability and safety standards.