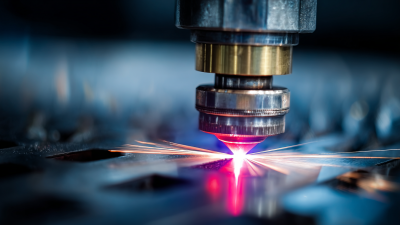

The advent of the Steel Laser Cutter has marked a significant transformation in the metal fabrication industry, balancing precision with speed in ways previously unimaginable. According to a report by MarketsandMarkets, the laser cutting market is projected to reach $6.7 billion by 2025, fueled by advancements in technology and increased demand for custom metal parts. Steel Laser Cutters provide unparalleled accuracy, reducing waste and enhancing production efficiency, which is crucial in a landscape where manufacturers strive to meet the rising demands for quality and quick turnaround times. With the ability to cut complex shapes with tight tolerances, steel laser cutting has become the preferred method for various industries, including automotive, aerospace, and construction. As we explore the efficiency of Steel Laser Cutters, it’s essential to understand how their integration is revolutionizing the fabrication processes, influencing operational costs, and ultimately elevating product quality across the board.

Steel laser cutting technology represents a significant advancement in the metal fabrication industry, offering unmatched precision and speed. At its core, laser cutting utilizes a focused beam of light to slice through materials with remarkable accuracy. This technology not only minimizes waste but also ensures intricate designs can be achieved without compromising on quality. The growing demand for laser cutters is reflected in the projected market growth, expected to reach USD 3.35 billion by 2034, driven by industries seeking efficient production methods.

Tips for optimizing laser cutting processes include understanding the four foundational elements of laser cutting quality: beam quality, cutting speed, focus, and material properties. Each factor plays a vital role in determining the overall efficiency and outcome of the cutting process. Additionally, even with automation, the skill and knowledge of operators are crucial. Workers must grasp these fundamentals to effectively manage the equipment and achieve the desired results. This knowledge not only enhances productivity but also mitigates the risks of errors and material losses in the fabrication process.

The efficiency of steel laser cutters in metal fabrication is significantly influenced by several key factors. One of the primary elements is the type of laser used. Different lasers, such as fiber or CO2, have varying wavelengths and energy outputs, affecting the cut quality and speed. Fiber lasers, for example, are known for their higher efficiency and faster cutting speeds on thinner materials, making them ideal for precision tasks. On the other hand, CO2 lasers tend to perform better on thicker metals but may require longer processing times.

Another crucial factor is the cutting parameters, including speed, power, and focal point. Optimizing these settings can drastically enhance the efficiency of the cutting process. For instance, increasing the cutting speed while maintaining adequate power ensures quicker operations without compromising the integrity of the cut. Additionally, the focus position of the laser beam plays a pivotal role in determining the kerf width and overall cut quality. Thus, careful adjustment and calibration of these parameters are essential for maximizing the performance of steel laser cutters in a competitive manufacturing environment.

Optimizing laser cutter settings is crucial for achieving the best results in metal fabrication. When beginning the setup process, it's essential to consider the type of material being cut. Different metals, such as stainless steel, aluminum, and mild steel, require specific power and speed adjustments. Begin by selecting the appropriate wattage for your laser cutter, as higher wattages can cut through thicker materials more efficiently. For thinner sheets, lower wattages can provide cleaner cuts and reduce the risk of burning or melting the edges.

Next, adjust the cutting speed to match the power settings. Slower speeds can enhance precision, allowing the laser to produce finer details in intricate designs. However, if the speed is too slow, it may lead to excessive heat buildup, resulting in warped materials. A good rule of thumb is to start with a speed that allows for reasonable cutting times while monitoring the cut quality. Finally, ensure the focus of the laser is set correctly; precise focal length is key to achieving optimal depth and clarity. Fine-tuning these settings through trial and error will ultimately lead to a more efficient and effective laser cutting process.

The cost-benefit analysis of laser cutters compared to traditional metal fabrication methods highlights the significant advantages offered by laser cutting technology. According to a report by the *Fabricators & Manufacturers Association*, laser cutting can reduce operational costs by up to 30% when evaluating energy consumption and labor efficiency. Traditional methods often require multiple setups, extensive labor, and higher material waste, while laser cutters provide the ability to perform intricate cuts with minimal handling, thus saving both time and resources.

Moreover, the precision of laser cutting minimizes the need for secondary processing, which is a common requirement in traditional methods. A study published in the *International Journal of Advanced Manufacturing Technology* notes that laser cutting results in a quality improvement of about 25%, reducing rework and scrap rates. This enhanced precision not only increases throughput but also allows for more complex designs that would be challenging or impossible to achieve with traditional techniques. Consequently, investment in laser cutting technology not only pays off through operational savings but also opens new avenues for innovation in metal fabrication, making it a compelling option for manufacturers looking to stay competitive in the evolving market.

| Criteria | Laser Cutters | Traditional Methods |

|---|---|---|

| Cutting Speed (m/min) | 20 - 30 | 5 - 10 |

| Thickness Range (mm) | 0.5 - 20 | 1 - 25 |

| Accuracy (mm) | ±0.05 | ±0.5 |

| Setup Time (hours) | 1 - 2 | 3 - 5 |

| Operational Cost ($/hour) | 25 - 45 | 20 - 40 |

| Material Waste (%) | 2 - 5 | 10 - 15 |

| Initial Investment ($) | 100,000 - 300,000 | 30,000 - 100,000 |

The landscape of laser cutting technology is evolving rapidly, driven by advancements in precision and automation. Recent industry reports indicate that the global market for laser cutting machines is projected to reach $5.2 billion by 2026, growing at a CAGR of 6.2% from 2021. This shift is not only catalyzing efficiency in metal fabrication but is also enabling manufacturers to leverage advanced materials and intricate designs that were previously unattainable with traditional methods.

In particular, the integration of AI and machine learning into laser technology is revolutionizing applications across various sectors, from automotive to aerospace. These innovations allow for real-time monitoring and adjustments during the cutting process, minimizing waste and maximizing yield. For instance, data suggests that companies employing smart laser systems report a 20% increase in production efficiency compared to their non-smart counterparts.

Tips: To adapt to these future trends, businesses should invest in training their workforce on new technologies and emphasize the importance of continuous learning. Additionally, exploring partnerships with tech firms can lead to more innovative solutions tailored to specific manufacturing needs. Finally, monitoring industry reports regularly will help companies stay ahead of the curve and make informed investment decisions.