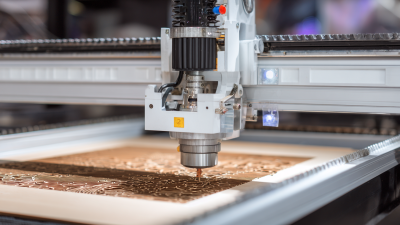

In the rapidly evolving landscape of modern manufacturing, the introduction of the Fiber Laser Cutting Machine stands out as a game changer. With its unparalleled precision and efficiency, this advanced technology is transforming how industries approach cutting and shaping materials. From automotive to aerospace, manufacturers are harnessing the power of fiber lasers to achieve intricate designs and reduce waste, leading to significant cost savings and improved production timelines. As traditional cutting methods struggle to keep pace with the demands for greater accuracy and versatility, fiber laser cutting machines offer a compelling solution that not only enhances productivity but also elevates the quality of finished products. This integration of innovation into manufacturing processes marks a pivotal shift, showcasing the potential of fiber laser technology to redefine industry standards and drive competitive advantage.

Fiber laser cutting machines are transforming the landscape of modern manufacturing by enhancing efficiency and precision in various processes. One of the key benefits of these machines is their ability to deliver high-speed cutting with remarkable accuracy. Unlike traditional cutting methods, fiber lasers can cut through diverse materials, such as metals and plastics, at impressive speeds while maintaining tight tolerances. This not only increases production rates but also minimizes material waste, allowing manufacturers to optimize their resources effectively.

Moreover, fiber laser cutting machines are known for their low operational costs and minimal maintenance requirements. Their design eliminates the need for complex optical components, reducing the time and resources needed for upkeep. This efficiency translates into lower energy consumption and prolonged equipment lifespans, making fiber lasers an economical choice for manufacturers. As industries continue to seek innovative solutions for productivity, the integration of fiber laser technology promises to drive substantial improvements in manufacturing efficiency, ultimately leading to more streamlined operations and greater competitiveness in the market.

Fiber laser cutting machines represent a significant advancement over traditional cutting methods such as plasma and waterjet cutting. The key distinction lies in their operational mechanism. Fiber lasers utilize a concentrated beam of light generated by optical fibers, allowing for greater precision and speed. This enables them to produce intricate designs and handle various materials, including metals and plastics, with minimal heat distortion. In contrast, traditional methods often suffer from slower cutting speeds and less detailed finishes, which can impact the overall quality of the final product.

Moreover, the efficiency of fiber laser cutting machines extends to material wastage and energy consumption. Fiber lasers typically require less power and produce less scrap compared to traditional methods, making them not only cost-effective but also environmentally friendly. The ability to automate and integrate with modern manufacturing processes further enhances their appeal, providing manufacturers with the agility to meet the demands of a dynamic market. Overall, the comparative analysis between fiber laser technology and conventional cutting techniques highlights a clear shift towards more innovative and efficient solutions in the manufacturing landscape.

Fiber laser cutting machines are becoming a cornerstone of modern manufacturing, offering enhanced precision and efficiency in cutting various materials. One of the essential features of these machines is their ability to deliver high-quality cuts with minimal waste. The focused beam of light ensures that even delicate materials can be processed without compromising their integrity. Additionally, the adaptability of fiber lasers allows them to cut through metals, plastics, and even ceramics, making them versatile tools in various industries.

When considering a fiber laser cutting machine, it’s vital to evaluate its power output. Higher wattage can significantly improve cutting speeds and the thickness of materials you can work with. Tip: Ensure that the machine you choose aligns with your business needs, whether it's for intricate designs or mass production.

Another key feature to look for is automation capabilities. Modern fiber laser cutting machines often come equipped with advanced software that optimizes the cutting path, reducing time and material costs. Tip: Investing in a machine that integrates well with your existing workflow can enhance productivity and streamline operations, offering substantial long-term savings.

Implementing fiber laser technology in your manufacturing process can lead to remarkable improvements in efficiency and precision. One essential tip for optimizing production is to ensure that your machine settings are calibrated correctly. Fine-tuning parameters such as power, speed, and focus can significantly enhance cutting quality and speed. Regular maintenance checks, including lens cleaning and alignment verification, are crucial to prevent downtime and maintain optimal performance.

Additionally, choosing the right materials and optimizing their placement on the cutting bed can minimize waste and maximize productivity. For complex designs, employing nesting software can help arrange parts more efficiently. This not only saves material but also reduces the overall cutting time. As operators become more familiar with fiber laser capabilities, leveraging advanced features like automation and integrated software systems can further streamline workflows, ultimately transforming your manufacturing operations into a more agile and responsive environment.

As the manufacturing landscape continuously evolves, fiber laser cutting technology is at the forefront of innovative practices. A recent report has identified key trends that are shaping the future of this technology. Notably, the integration of automation and artificial intelligence in laser cutting processes is proving to enhance efficiency and precision. Executives in the additive manufacturing sector have noted that by 2025, nearly 75% of companies are expected to adopt AI-driven solutions to optimize production workflows, significantly reducing turnaround times and costs.

Furthermore, the rise of sustainable manufacturing practices is prompting a shift in how laser cutting technologies are utilized. According to industry analysis, over 60% of leading companies in laser technology are investing in eco-friendly materials and processes, reflecting a growing emphasis on sustainability. Meanwhile, a survey of startups reveals that approximately 20 out of 680 startups are focusing on developing novel applications of fiber laser cutting, further indicating penetration into niche markets and enhanced manufacturing capabilities. As these trends unfold, businesses must adapt and leverage fiber laser technologies to stay competitive in a rapidly transforming landscape.

| Feature | Details | Impact on Manufacturing |

|---|---|---|

| Speed | Up to 30% faster cutting compared to traditional methods | Increases production efficiency and reduces lead time. |

| Material Flexibility | Works with various materials like metals, plastics, and glass | Expands capability for manufacturers to diversify products. |

| Precision | Accuracy within 0.01 mm | Reduces waste and improves product quality. |

| Cost-Effectiveness | Lower operational costs due to reduced energy consumption | Increases profitability and sustainability. |

| Automation | Integration with automation systems like robotics | Enhances production workflows and minimizes human error. |

| Future Trends | Smart factories and Industry 4.0 integration | Drives innovation and adapts to market changes rapidly. |