Mastering the art of cutting with a Fiber Laser Cutter is not only about wielding advanced technology but also understanding the principles and techniques that underpin effective laser cutting. As industries increasingly adopt fiber laser cutting for its precision, speed, and versatility, knowing how to optimize this process becomes essential for both hobbyists and professionals alike.

This guide aims to provide you with insightful tips and expert advice to enhance your skills with a Fiber Laser Cutter, covering everything from material selection and machine settings to safety precautions and maintenance practices. Whether you're creating intricate designs or large-scale projects, mastering these techniques will empower you to achieve exceptional results while maximizing the capabilities of your Fiber Laser Cutter.

Join us on this journey to unlock the full potential of laser cutting and elevate your craftsmanship to new heights.

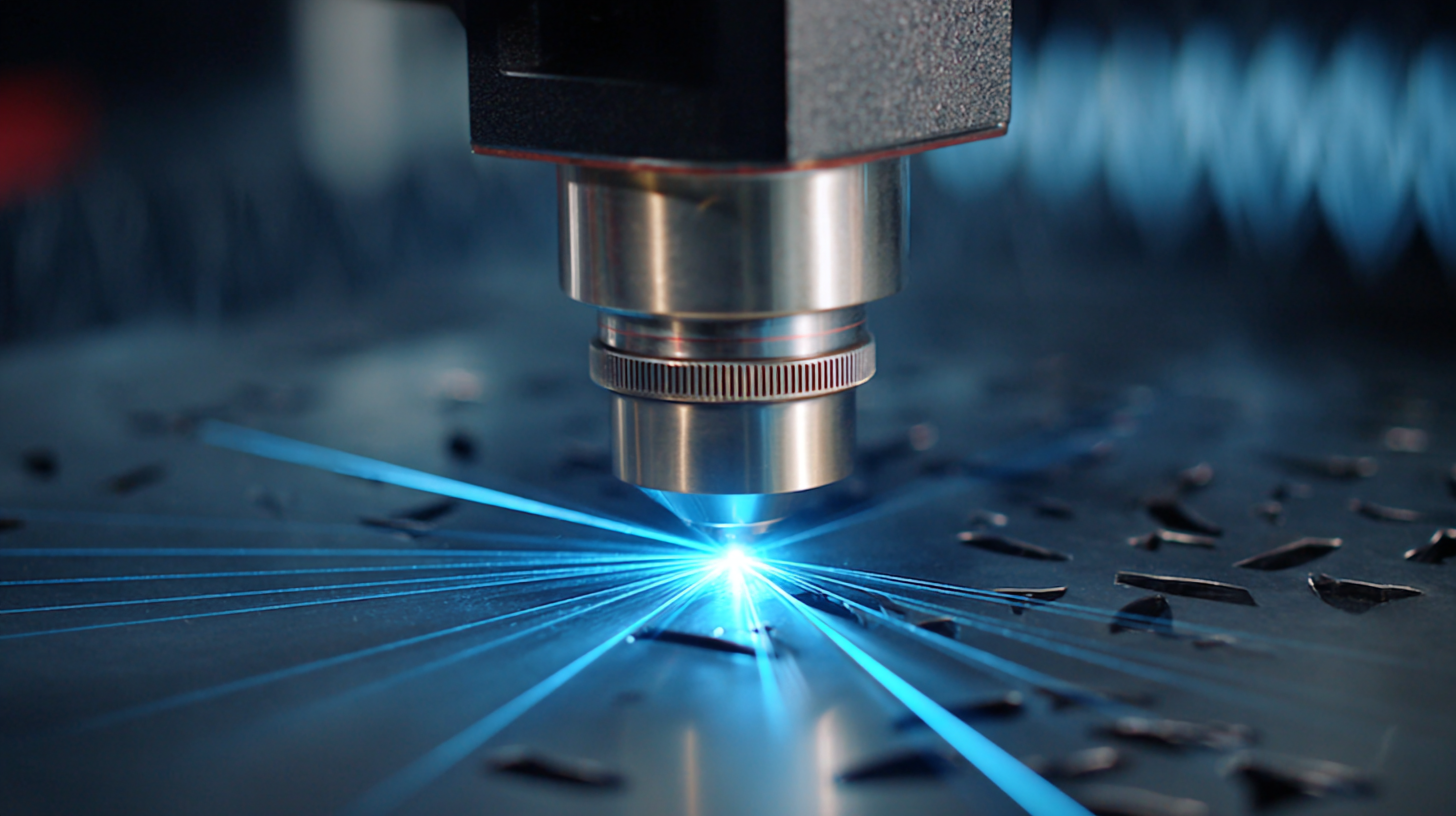

Fiber laser cutting technology has revolutionized the manufacturing industry by offering unmatched precision and efficiency. At its core, fiber laser cutting utilizes a solid-state laser, which is generated from a fiber optic cable, to produce a focused beam of light. This technology is known for its exceptional beam quality, which allows for finer cuts and intricate designs at high speeds.

According to a 2022 market analysis by Grand View Research, the global fiber laser market is expected to reach $5.53 billion by 2028, growing at a CAGR of 10.6%. This indicates a rapidly increasing adoption of fiber lasers in industrial applications.

Fiber laser cutting technology has revolutionized the manufacturing industry by offering unmatched precision and efficiency. At its core, fiber laser cutting utilizes a solid-state laser, which is generated from a fiber optic cable, to produce a focused beam of light. This technology is known for its exceptional beam quality, which allows for finer cuts and intricate designs at high speeds.

According to a 2022 market analysis by Grand View Research, the global fiber laser market is expected to reach $5.53 billion by 2028, growing at a CAGR of 10.6%. This indicates a rapidly increasing adoption of fiber lasers in industrial applications.

One of the primary advantages of fiber laser cutting is its ability to cut a wide range of materials, including metals, plastics, and even wood, with ease. The efficiency of fiber lasers significantly reduces operational costs, as they require less energy compared to traditional CO2 lasers. A report from Research and Markets highlighted that fiber laser systems can achieve cutting speeds up to 4 times faster than CO2 systems, making them ideal for both high-volume production and bespoke projects. With advancements in technology, it is clear that mastering fiber laser cutting can provide a competitive edge in today’s fast-paced manufacturing landscape.

Operating a fiber laser cutter requires stringent safety measures to minimize risks associated with high-speed, high-energy operations. According to a report by the Occupational Safety and Health Administration (OSHA), improper use of laser cutters can lead to severe injuries, including burns and eye damage. To safeguard operators, it is essential to wear appropriate personal protective equipment (PPE), such as safety glasses with proper laser ratings and flame-resistant clothing. Moreover, ensuring the workspace is free from flammable materials can significantly reduce the likelihood of accidents.

Another critical aspect of safety is maintaining a clear line of sight and proper ventilation in the workspace. The American National Standards Institute (ANSI) recommends regular inspections of laser equipment and surrounding areas to ensure that safety protocols are in place. This includes having emergency stop buttons easily accessible and training personnel on proper emergency response procedures. Furthermore, implementing a User Manual in accordance with the manufacturer’s guidelines ensures that operators are aware of specific safety features and functions that can aid in safe operation. By prioritizing both personal and environmental safety, operators can master the art of cutting with a fiber laser cutter effectively and securely.

When it comes to mastering the art of cutting with a fiber laser cutter, selecting the right materials is crucial for achieving optimal results. According to a report by the International Laser Manufacturing Society, the efficiency of fiber laser cutting can be significantly affected by the type of material used. For instance, materials like stainless steel, aluminum, and carbon steel can display different cutting speeds and kerf widths, directly influencing the quality of the cut. Utilizing materials with suitable thicknesses can also affect the power settings needed for effective cutting, emphasizing the importance of careful material selection.

Additionally, the surface finish and physical properties of the materials play vital roles in the cutting process. A recent study published in the Journal of Applied Physics indicated that materials with high reflectivity, such as copper and brass, require specialized techniques and settings to achieve desirable results. The report highlights that applying a coating or using a hybrid laser cutting approach can mitigate reflective losses, thus enhancing productivity. Understanding these dynamics not only aids operators in achieving high-quality cuts but also in optimizing the fiber laser cutter's performance, ultimately leading to improved operational efficiency and cost savings in industrial applications.

| Material | Thickness (mm) | Cutting Speed (mm/min) | Power (W) | Notes |

|---|---|---|---|---|

| Mild Steel | 1.0 | 300 | 1500 | Great for general cutting |

| Stainless Steel | 1.5 | 200 | 2000 | Requires precise settings |

| Aluminum | 2.0 | 250 | 3000 | Fast cutting speed |

| Acrylic | 5.0 | 600 | 1000 | Produces clean edges |

| Copper | 0.8 | 150 | 2500 | Difficult to cut |

Setting up and adjusting your fiber laser cutter is crucial for achieving precision and efficiency in your cutting projects. Begin by ensuring that your machine is on a stable, flat surface to minimize vibrations that could affect performance. Check the alignment of the laser head and the focus lens, as accurate positioning significantly impacts the quality of the cut. Regularly cleaning these components will help maintain optimal functionality.

Tips for setting up your fiber laser cutter include calibrating the focal length carefully. Use a piece of scrap material to test the focus before starting your actual project. Additionally, adjusting the cutting speed and power settings according to the material type is essential. For instance, thicker materials typically require slower cutting speeds and higher power levels for precise cuts. Always keep a log of your settings for different materials to streamline future projects.

When adjusting your fiber laser cutter, pay attention to the airflow. Proper ventilation prevents the buildup of smoke and debris, enhancing the cutting quality. It's also advisable to conduct regular maintenance checks on the optics and cooling systems to ensure consistent performance. With these techniques and tips, mastering the fiber laser cutter will become a seamless process.

Fiber laser cutting has revolutionized the manufacturing landscape, but it comes with its own set of challenges. Common issues include difficulties in achieving precise cuts and dealing with material distortion. According to a report by MarketsandMarkets, the global fiber laser market is projected to reach $3.3 billion by 2025, indicating a growing reliance on this technology in industries like automotive and aerospace. To tackle precision issues, operators must ensure optimal focus lens selection and machine settings. Regularly cleaning the optics is crucial as contamination can drastically impact cut quality.

Another significant challenge is managing heat-affected zones and warping of materials. A study from the Journal of Materials Processing Technology highlights that inadequate cooling can lead to thermal stress, compromising the integrity of the final product. Implementing advanced cooling techniques and understanding the thermal conductivity of materials is essential for minimizing these effects. By addressing these common challenges through careful preparation and methodical adjustments, manufacturers can harness the full potential of fiber laser cutting to produce high-quality, precise components efficiently.