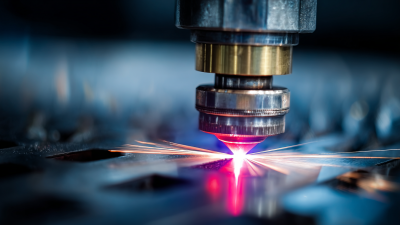

In today’s fast-paced manufacturing environment, precision and efficiency are paramount. Among the various technologies that have transformed the landscape of fabrication, Stainless Steel Laser Cutting stands out as a revolutionary method that significantly enhances the capabilities of precision manufacturing. This modern technique utilizes highly focused laser beams to cut through stainless steel with impeccable accuracy, minimizing waste and maximizing production speed. The precision offered by this method allows manufacturers to achieve intricate designs and complex geometries that would be challenging to produce using traditional cutting methods.

In today’s fast-paced manufacturing environment, precision and efficiency are paramount. Among the various technologies that have transformed the landscape of fabrication, Stainless Steel Laser Cutting stands out as a revolutionary method that significantly enhances the capabilities of precision manufacturing. This modern technique utilizes highly focused laser beams to cut through stainless steel with impeccable accuracy, minimizing waste and maximizing production speed. The precision offered by this method allows manufacturers to achieve intricate designs and complex geometries that would be challenging to produce using traditional cutting methods.

The growing demand for high-quality components across various industries, from automotive to aerospace, underscores the importance of advanced manufacturing techniques. Stainless Steel Laser Cutting not only improves the quality of the cut surfaces but also ensures that the tolerance levels are maintained to the highest standards. This capability enables manufacturers to meet stringent industry requirements while reducing operational costs. Furthermore, as industries increasingly lean towards automation and smart manufacturing solutions, the integration of laser cutting technology plays a crucial role in enhancing overall productivity, reliability, and workflow efficiency.

As we delve deeper into the intricacies of Stainless Steel Laser Cutting, we will explore how this innovative technique is shaping the future of precision manufacturing, the advantages it brings to the table, and the potential it holds for advancing industrial processes. The ongoing evolution of this technology promises to unlock new opportunities for manufacturers striving for excellence in their production capabilities.

Stainless steel laser cutting is a revolutionary technology that uses high-powered lasers to cut through stainless steel sheets with unparalleled precision. This advanced method offers significant advantages over traditional cutting techniques, particularly in terms of accuracy and finish quality. Laser cutting utilizes focused light beams to melt or vaporize the metal, resulting in clean, smooth edges without the need for extensive post-processing. This level of precision is essential for manufacturing components that require tight tolerances and intricate designs.

Understanding the basics of stainless steel laser cutting technology begins with its mechanism. The laser cutting machine directs a concentrated laser beam onto the stainless steel surface, which is often coupled with a gas assist, such as oxygen or nitrogen, to enhance the cutting process. The controlled nature of the laser allows for rapid movement and the ability to change shapes and patterns easily, ensuring flexibility in design. This technology not only streamlines production but also reduces material waste, making it an efficient solution for modern manufacturing environments. Additionally, the repeatable accuracy achieved through laser cutting minimizes errors, ultimately enhancing the overall quality of manufactured products.

Laser cutting has revolutionized precision manufacturing, particularly in the realm of stainless steel. One of the primary advantages of using laser cutting is its unparalleled accuracy. The high-intensity laser beam enables manufacturers to achieve intricate designs and tight tolerances that would be difficult to replicate using traditional cutting methods. This level of precision not only enhances the aesthetic appeal of the final product but also ensures optimal functionality in applications where precise dimensions are crucial.

Additionally, laser cutting offers significant efficiency benefits. The process is highly automated, reducing the reliance on manual labor and decreasing production times. With minimal material waste due to the narrow kerf width, manufacturers can cut more components from a single sheet of stainless steel, thereby lowering costs. Moreover, the heat-affected zone is significantly smaller compared to other cutting techniques, which helps maintain the integrity of the metal. This efficiency, combined with the precision it delivers, makes laser cutting a superior choice for manufacturers looking to enhance their production capabilities while maintaining high-quality standards.

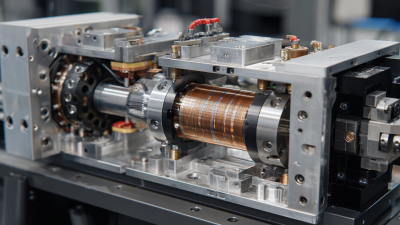

Stainless steel laser cutting is rapidly becoming an essential process across numerous industries, thanks to its precision and efficiency. In the automotive sector, for instance, the adoption of laser cutting technology has surged by approximately 30% in the last five years, primarily due to the demand for intricate designs and lightweight components. This method allows manufacturers to achieve tight tolerances, which is crucial for components such as brackets, supports, and chassis parts.

In the aerospace industry, stainless steel laser cutting plays a vital role in the production of complex components while minimizing material waste. According to a recent market analysis, the aerospace sector is expected to see a compound annual growth rate (CAGR) of 5.5% for laser processing technologies over the next decade. The ability to cut advanced materials with superior accuracy ensures that manufacturers can improve safety and performance metrics in their designs.

**Tips:** When considering stainless steel laser cutting for your projects, always assess the thickness and type of stainless steel being used, as these factors significantly impact the laser's efficiency. Additionally, investing in regular maintenance for your laser cutting equipment can lead to enhanced precision and longer tool life, further optimizing your manufacturing processes.

| Industry | Applications | Benefits of Laser Cutting | Precision Level |

|---|---|---|---|

| Automotive | Chassis components, brackets, and other structural parts | High accuracy, minimal heat affected zone | Micro-meter |

| Aerospace | Components of aircraft, engine parts | Lightweight and strong cuts | Micro-meter |

| Medical | Surgical instruments, implants | Sterile cut without contamination | Nano-meter |

| Construction | Structural steel, architectural design | Complex geometries, precision assembly | Millimeter |

| Electronics | Enclosures, circuit board parts | Detail-driven precision, clean edges | Micro-meter |

Laser cutting has revolutionized the manufacturing industry, particularly in the processing of stainless steel. This method utilizes focused laser beams to cut materials with incredible precision and speed. Unlike traditional cutting methods, such as mechanical saws or plasma cutting, laser cutting minimizes material waste while enhancing operational efficiency. According to a report by Grand View Research, the global laser cutting machine market is projected to reach $6.50 billion by 2025, primarily driven by the demand for high-precision manufacturing that traditional methods struggle to meet.

In terms of precision, laser cutting achieves tolerances as close as ±0.005 inches, which outperforms traditional methods that typically fall within ±0.01 to ±0.05 inches. Additionally, the heat-affected zone (HAZ) is significantly smaller with laser cutting, reducing the risk of warping and ensuring the integrity of the stainless steel. A study conducted by the International Journal of Advanced Manufacturing Technology highlighted that laser cutting produced up to 90% less kerf width compared to mechanical cutting processes, further solidifying its status as a superior choice in precision manufacturing. As industries continue to demand higher accuracy and lower production costs, laser cutting stands out as the clear leader in the field.

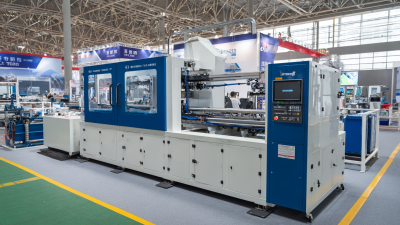

Recent trends in stainless steel laser cutting emphasize the growing integration of advanced technologies that enhance precision manufacturing. The laser welding market itself is projected to reach USD 4.2 billion by 2035, demonstrating a compound annual growth rate (CAGR) of 3.7% from 2025 to 2035. This growth reflects the increasing adoption of high-power laser applications across various industries, significantly improving productivity and precision.

Additionally, the exploration of high-power laser cutting, welding, and drilling has yielded remarkable benefits, such as reduced material wastage and increased cutting speeds. Numerous startups are emerging in this space—over 680 have been identified—bringing innovative solutions that cater to the evolving demands of precision engineering. As the CNC machine market continues to expand, expected to grow exponentially by 2032, it highlights the transformative nature of digital manufacturing technologies. These advancements not only enhance operational efficiency but also create new opportunities for businesses seeking to remain competitive in an increasingly automated landscape.