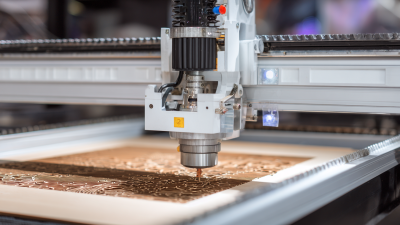

As we venture into 2025, the landscape of manufacturing and design is being reshaped by cutting-edge technologies, prominently featuring the CNC laser cutting machine. These advanced tools provide unparalleled precision and efficiency, leading the charge in the field of innovation. According to industry expert Dr. Emily Carter, a leading authority in laser technology, "The future of fabrication lies in the capabilities of CNC laser cutting machines, enabling designers and manufacturers to explore new frontiers in creativity and efficiency."

In 2025, CNC laser cutting technology continues to evolve, driving innovation in precision manufacturing. As industries increasingly demand personalized processing capabilities, the role of advanced laser cutting techniques becomes paramount. This technology allows for intricate designs and shapes, enhancing product quality while optimizing production efficiency. In regions like Harbin, specialized cutting service providers are emerging to meet these unique demands, showcasing their expertise in handling complex geometries that traditional methods struggle with.

The market for portable cutting machines is on the rise, reflecting a broader trend towards versatile, user-friendly solutions in manufacturing. With a projected value increase from approximately $4.3 billion in 2024 to $7.77 billion by 2033, the sector is expected to grow at a compound annual growth rate of about 6.8%. This surge illustrates the industry's shift towards more adaptable tools that cater to diverse cutting needs, ensuring businesses can remain competitive in an ever-evolving landscape. As CNC laser cutting technology progresses, it empowers manufacturers to further unlock their potential through innovation and efficiency.

CNC laser cutting machines are revolutionizing the manufacturing landscape, offering significant advantages that are driving their adoption in various industries. By 2025, the global machine tool market is projected to grow from $132.63 billion to $229.46 billion by 2032, maintaining a compound annual growth rate (CAGR) of 8.1%. This growth is fueled by the increasing demand for precision and efficiency in production processes. CNC laser cutting machines excel in these areas, enabling manufacturers to achieve intricate designs while minimizing material wastage and operational costs.

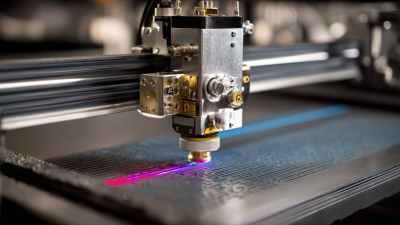

The key advantages of using CNC laser cutting technology include enhanced speed, accuracy, and versatility. Unlike traditional cutting methods, CNC lasers can swiftly cut through a variety of materials, including metals and plastics, with precision tolerances that are difficult to achieve with manual processes. Additionally, the global market for CNC machining centers is estimated to grow from $14.35 billion in 2025 to $21.69 billion by 2033, reflecting a growth rate of 5.7%. This trend highlights the increasing reliance on automated solutions like CNC lasers in modern manufacturing practices, reinforcing their role as essential tools for innovation and competitive advantage in the industry.

CNC laser cutting machines have revolutionized the manufacturing landscape, offering unmatched precision and efficiency for various applications. As we move towards 2025, understanding the different types of CNC laser cutting machines is essential for businesses looking to optimize their production processes. The market is likely to experience significant growth, with an expected CAGR of 3.6% from 2025 to 2032, driven by advancements in technology and increased demand across multiple sectors.

When exploring CNC laser cutting machines, it's important to consider the various applications. Machines are categorized by type, such as mechanical and hydraulic models, each suited for different manufacturing needs. Industries like automotive and aerospace utilize specialized machines that can handle specific materials, including aluminum and steel. Automation levels also play a key role, with options ranging from manual to fully automated systems.

Tip: When selecting a CNC laser cutting machine, evaluate your production volume and material types to ensure the best fit for your operations. Choosing the right machine can significantly impact efficiency and operational costs. Additionally, consider future scalability and technology upgrades to stay competitive in the evolving market.

CNC laser cutting technology is revolutionizing the manufacturing sector by offering unprecedented precision and efficiency. As businesses strive for innovation in a competitive market, the integration of CNC laser cutting machines enables manufacturers to create complex designs with minimal waste. This advanced technology allows for intricate patterns and shapes to be cut from various materials, including metals, plastics, and wood, all while maintaining tight tolerances. The adaptability of CNC laser cutting makes it an invaluable asset in industries ranging from aerospace to fashion, enhancing the ability to prototype and produce on-demand.

Moreover, CNC laser cutting machines significantly enhance production processes by reducing lead times and production costs. The automation provided by CNC systems means that manufacturers can achieve higher output rates without sacrificing quality. Consequently, companies can respond more swiftly to market demands, promoting a culture of innovation where new ideas can be transformed into tangible products rapidly. By fostering a seamless flow from design to production, CNC laser cutting not only streamlines operations but also empowers manufacturers to push the boundaries of creativity and innovation in their products and processes.

| Dimension | Details |

|---|---|

| Cutting Speed | Up to 30m/min |

| Laser Power Options | 100W, 200W, 500W |

| Materials Supported | Metal, Wood, Acrylic, Fabric |

| Precision | ±0.1mm |

| Max Cutting Thickness | 25mm for Steel, 20mm for Acrylic |

| Cooling System | Water Cooling |

| Control Software | Compatible with CAD/CAM Software |

| Automation Features | Auto Focus, Smart Height Control |

| Application Industries | Automotive, Aerospace, Architecture |

As we look towards 2025, the CNC laser cutting technology is expected to undergo significant advancements, driven by the increasing demand across various industrial sectors. The metal manufacturing market is projected to reach a staggering $10081.8 billion by 2033, showcasing a robust compound annual growth rate (CAGR) of 3.1% from 2025. This growth is largely fueled by the need for higher precision and efficiency in production processes. Industries are progressively shifting towards automated solutions, enhancing productivity and reducing operational costs.

Tips: When considering CNC laser cutting machines, it’s crucial to evaluate the level of automation appropriate for your operations. A semi-automated or fully automated solution can significantly streamline your processes, ensuring consistent quality and reducing lead times.

Moreover, the application of CNC laser technology is anticipated to expand into sectors like aerospace and automotive, where intricate designs and materials such as aluminum and steel are prevalent. Choosing the right equipment tailored to your specific applications can make a substantial difference in achieving operational excellence.

Tips: Invest in training for your workforce on the latest CNC technology to fully leverage the capabilities of laser cutting machines. Proper training not only enhances safety but also maximizes the benefits of high-precision tools and innovations in manufacturing processes.