In today's rapidly evolving manufacturing landscape, the Metal Laser Cutting Machine stands out as a game-changer, offering unmatched precision and versatility for various industrial applications. As industries continuously seek to enhance efficiency and reduce production costs, metal laser cutting technology has emerged as a critical solution for transforming raw materials into intricately designed components. This blog aims to delve into the myriad types and functionalities of Metal Laser Cutting Machines, exploring their applications across different sectors, the benefits they offer, and the innovations that are shaping their future. Whether you're an industry veteran or a newcomer, understanding the capabilities of these machines is essential for harnessing their full potential and driving your business forward in a competitive market.

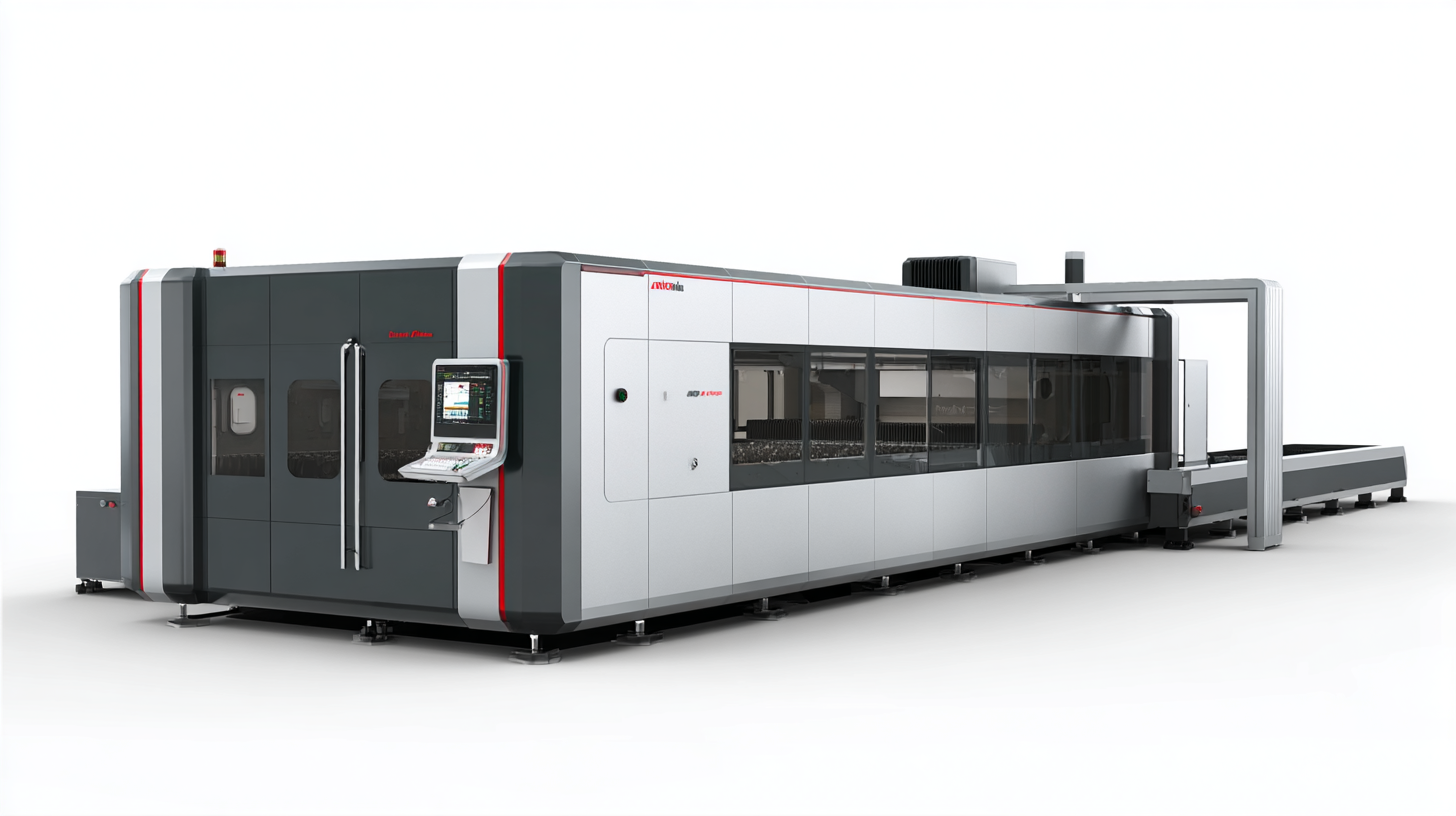

Metal laser cutting machines have become indispensable tools in various industries, owing to their precision and versatility. These machines utilize different technologies, including fiber lasers, CO2 lasers, solid-state lasers, and semiconductor lasers, each offering unique advantages. The choice of technology greatly influences the machine's performance, cost-effectiveness, and suitability for specific applications. For instance, fiber lasers are known for their efficiency and speed, making them ideal for high-production settings, while CO2 lasers are better suited for cutting thicker materials.

The functionality of metal laser cutting machines can also be categorized into semi-automatic and robotic systems. Semi-automatic machines require manual input for some processes, which can be beneficial for smaller operations seeking flexibility. In contrast, robotic laser cutting systems offer higher automation levels, catering to large-scale production by minimizing human intervention and maximizing speed and accuracy.

Tip: When selecting a metal laser cutting machine, assess your production needs carefully, including the types of materials you'll be cutting and the desired turnaround time. Additionally, evaluate the machine's compatibility with existing systems to ensure a seamless integration into your workflow. Investing in a machine with advanced features can significantly enhance efficiency and productivity.

When selecting the right metal laser cutting machine for your needs, it is crucial to consider various factors including material type, thickness, and desired precision. According to a recent industry report by MarketsandMarkets, the global laser cutting machine market is projected to reach $7.7 billion by 2026, with an annual growth rate of approximately 6.3%. This growth is primarily driven by the rising demand for automation and high precision in manufacturing processes, making it essential to choose a machine that aligns with your operational goals.

One critical aspect to evaluate is the wattage of the laser. Machines with higher wattages can cut through thicker materials at faster speeds. For instance, a 500-watt laser might effectively cut mild steel up to 5 mm thick, whereas a 2000-watt laser can handle up to 15 mm. Additionally, features such as CNC integration and advanced cooling systems can enhance efficiency and longevity. As reported by Research and Markets, sectors such as automotive and aerospace are increasingly adopting laser cutting due to its capacity to produce intricate designs with minimal waste, highlighting the importance of selecting a machine tailored to industry-specific requirements.

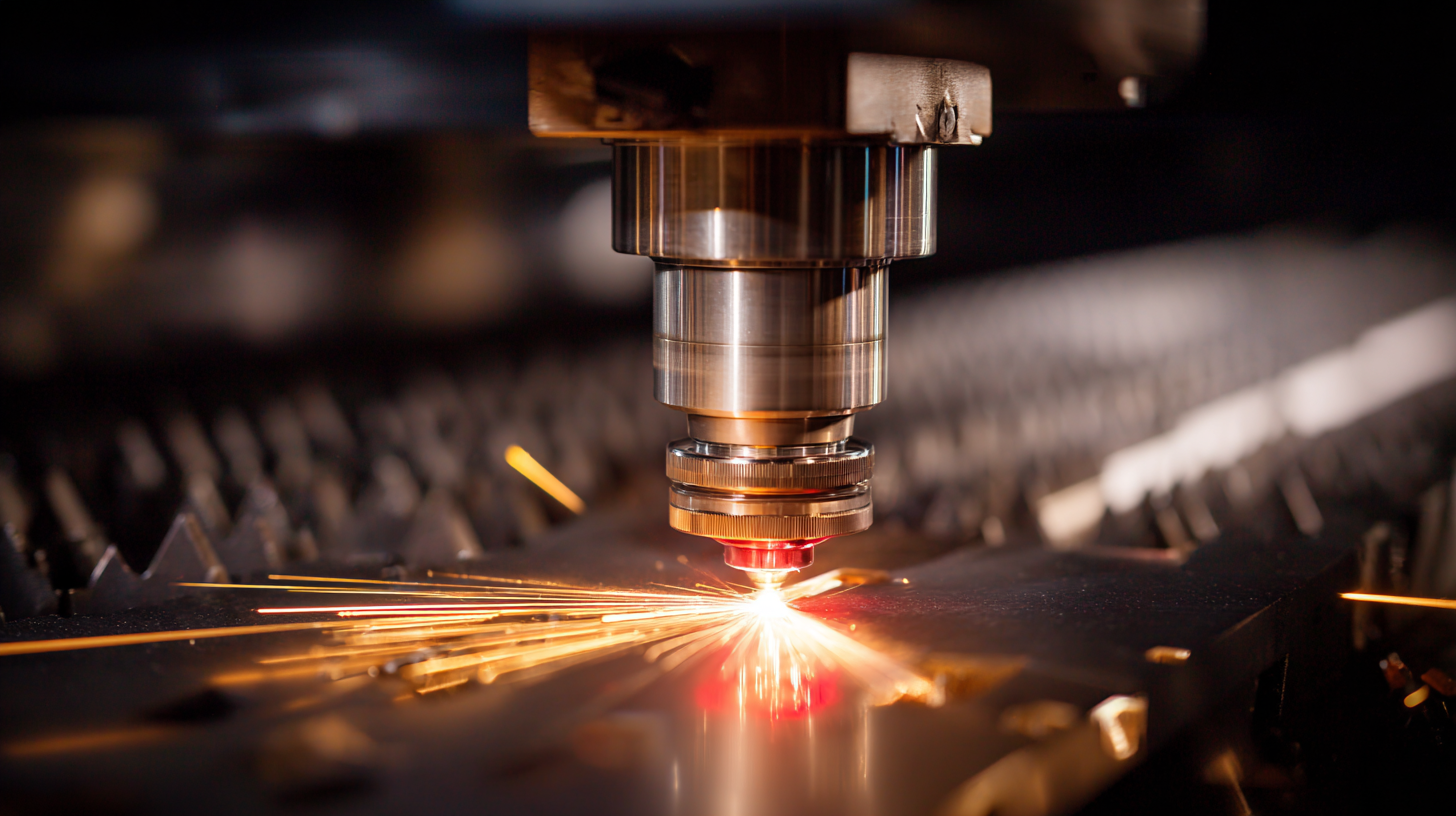

Operating a metal laser cutting machine involves a series of systematic steps to ensure precision and efficiency. First, it is crucial to select the appropriate metal type and thickness based on the project requirements. According to a report by the Laser Institute of America, fiber laser technology, for instance, can effectively cut through materials up to 25 mm thick, making it a go-to choice for industries ranging from automotive to aerospace. Following material selection, operators must configure the machine settings, including the cutting speed and power output, which are vital for achieving optimal cut quality and minimizing waste.

Next, proper machine calibration and alignment are essential before initiating the cutting process. This includes checking the focus of the laser beam and ensuring that the nozzle is clean to prevent any interference during operation. Industry data indicates that proper maintenance and regular calibration can enhance machine longevity by up to 30% and significantly reduce downtime. Once everything is set, operators can run test cuts to fine-tune the settings further, ensuring the final product meets the established specifications. Each of these steps not only ensures operational effectiveness but also significantly enhances the versatility and capabilities of metal laser cutting machines in modern manufacturing environments.

This chart illustrates the various applications of metal laser cutting machines across different industries, highlighting their versatility and importance.

Maintaining metal laser cutting machines is essential for ensuring their longevity and operational efficiency. Regular maintenance schedules should be established, focusing on key components such as the lens, mirrors, and nozzle. Cleaning these parts with appropriate materials prevents the buildup of debris that can impair cutting quality. Additionally, lubricating moving parts and checking for any signs of wear can help anticipate potential issues before they escalate into costly repairs.

Temperature control plays a crucial role in maintaining the performance of laser cutters. Machines should operate within a specified temperature range to avoid overheating, which can lead to damage or decreased efficiency. Implementing a routine inspection of cooling systems and ensuring the ventilation is unobstructed are vital steps in this process. Moreover, keeping software updates current can improve functionality and maintain cutting precision, further extending the machine's lifespan. By adhering to these maintenance tips, users can maximize the performance and durability of their metal laser cutting machines.

| Maintenance Tip | Frequency | Purpose | Expected Outcome |

|---|---|---|---|

| Clean Lenses and Mirrors | Weekly | Maximize cutting efficiency and quality | Improved cut quality and reduced downtime |

| Inspect Alignment | Monthly | Ensure accuracy in cuts | Consistent cutting precision |

| Check Cooling System | Monthly | Prevent overheating | Extended machine life |

| Lubricate Moving Parts | Quarterly | Reduce wear and tear | Smoother operation |

| Update Software | As needed | Utilize latest features and optimizations | Enhanced performance and capabilities |

Metal laser cutting machines have become indispensable tools in various industries, each leveraging their precision and efficiency to streamline production processes. In the automotive sector, for instance, these machines are employed to create intricate components that require high accuracy. The ability to cut through various metals with minimal thermal distortion ensures that parts such as brackets and frames fit perfectly into complex assemblies, thereby enhancing overall vehicle performance and safety.

In the aerospace industry, the versatility of metal laser cutting technology is equally critical. Aerospace components often demand stringent weight and dimensional specifications. Laser cutting machines enable manufacturers to achieve lightweight yet strong structures, which are essential for flight efficiency. By utilizing advanced laser technology, companies can produce parts like turbine blades and wing spars that meet rigorous standards without adding unnecessary weight.

Tip 1: When selecting a metal laser cutting machine, consider the specific materials you’ll be working with to ensure compatibility and optimal performance.

Tip 2: Regularly maintain and calibrate your laser cutting equipment to preserve accuracy and extend its operational lifespan, reducing downtime and costs.