Daily maintenance and upkeep of laser cutting machine

Preface

The maintenance of laser Tube Cutting machine is an important step to ensure the normal operation of the equipment and extend its service life. It mainly includes three parts: cooling system (to ensure constant temperature effect), optical path system (to ensure beam quality), and transmission system (to ensure normal operation).

Cooling system maintenance

Regularly replace the water inside the water cooler

The water inside the water-cooled machine (purified water, distilled water, antifreeze) needs to be replaced regularly, usually every 2-3 months. The quality and temperature of the circulating water will affect the service life of the pipe cutting machine, so it is recommended to use purified water.

Keep the water flow unobstructed

Cooling water is responsible for taking away the heat generated by the laser tube. The higher the water temperature, the lower the light output power (preferably 23-25 ℃ water temperature, with slightly different minimum water temperature settings for different lasers); When the water is cut off, the accumulation of heat inside the laser cavity can cause the tube end to explode and even damage the laser power supply.

Temperature regulation principle

Frequent rainfall and humid environments can easily lead to condensation inside the laser, which can cause damage or malfunction of the laser's electrical and optical components, thereby reducing the performance of the laser and even damaging it. Therefore, when changing seasons or local temperature changes, the temperature should be adjusted according to the following principles:

The water temperature in summer should be adjusted within the range of 27-28 ℃, and should not be lower than the dew point temperature of the environment inside the laser.

The winter water temperature should be adjusted within the range of 22-24 ℃, and should not be lower than the dew point temperature of the cutting head working environment.

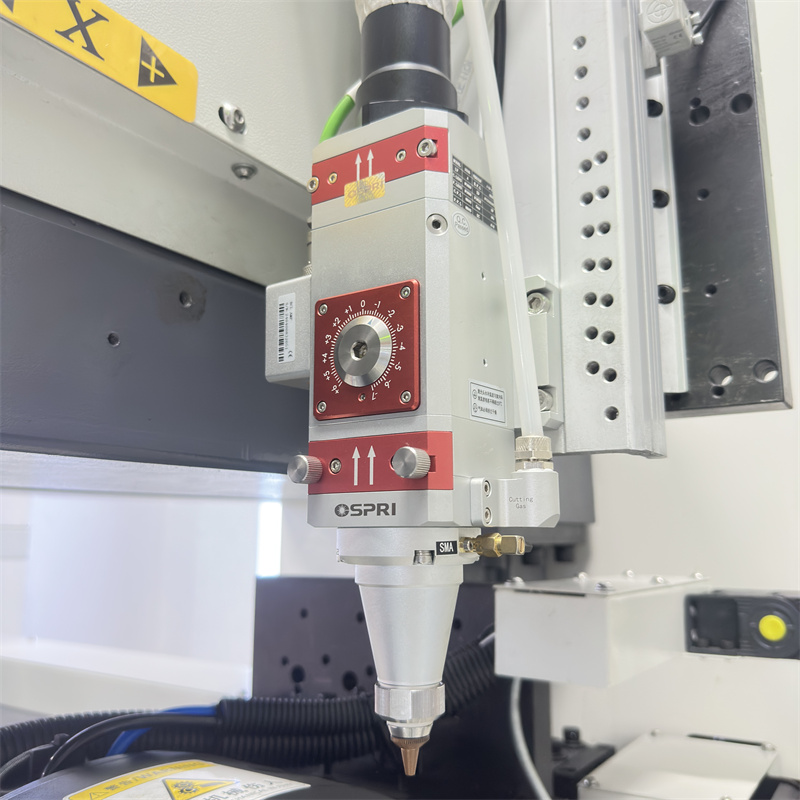

Maintenance of optical system

After the device works for a period of time, a layer of dust will stick to the surface of the lens due to the working environment, thereby reducing the reflectivity and transmittance of the reflective lens, ultimately affecting the working power of the laser.

Carefully use a degreased cotton dipped in alcohol to rotate and wipe along the center and edges of the lens. The lens should be gently wiped without damaging the surface coating; The wiping process should be handled gently to prevent falling.

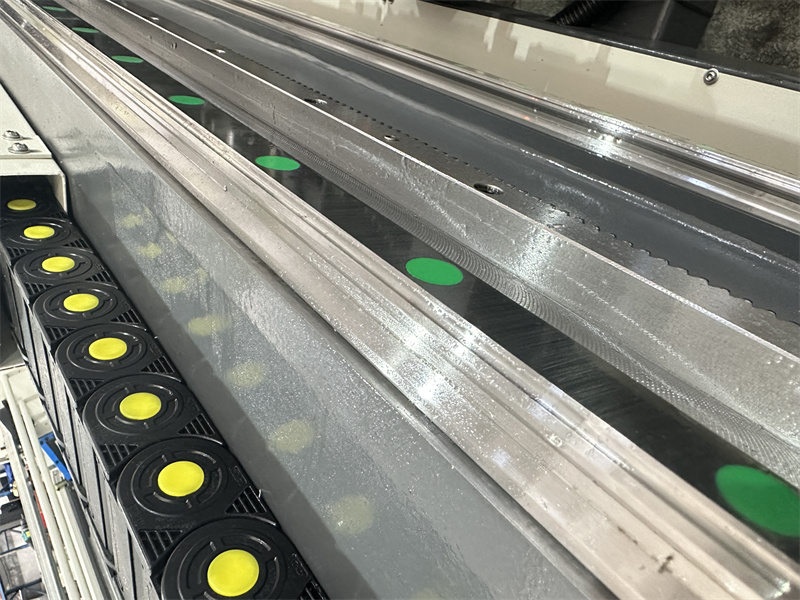

Maintenance of transmission system

During the long-term cutting process of the equipment, smoke and dust will be generated. Small smoke and dust will enter the equipment through the dust cover and adhere to the guide rail rack. Long term accumulation will increase the wear of the guide rail rack. In addition, rack and pinion guides are relatively precise components, and dust accumulates in large quantities on the surfaces of the guides and linear axes over a long period of time, which has a significant impact on the machining accuracy of the equipment and can form corrosion points on the surfaces of the guides and linear axes, shortening the service life of the equipment.

Therefore, in order to ensure the normal and stable operation of the equipment and the processing quality of the product, it is necessary to carefully maintain the guide rail and linear axis, regularly clean them with dust, apply butter to the rack, and lubricate the guide rail with lubricating oil. Each bearing should also be regularly lubricated to maintain flexible driving and precise machining, extending the service life of the machine tool.

Working environment

The environment of the workshop should be kept dry and well ventilated, with an ambient temperature of 4 ℃ -33 ℃. In summer, attention should be paid to preventing equipment condensation, and in winter, anti freezing measures should be taken for laser equipment.

The equipment should be kept away from electrical equipment that is sensitive to electromagnetic interference to prevent long-term exposure to electromagnetic interference, especially from sudden interference from high power and strong vibration equipment. High power interference can easily cause equipment failure.

Other precautions

Electrical system inspection: including cable connections, cleaning and heat dissipation inside the control cabinet, usage status of switch buttons, etc., to ensure the safe and reliable operation of the equipment.

Regular calibration: including optical path calibration, machine position calibration, etc., to ensure the machining accuracy and stability of the equipment.

Daily management: Establish and improve equipment usage records, record equipment operation and maintenance records, etc., in order to promptly identify and handle problems.

The above is the maintenance guide for the laser cutting machine. Through reasonable maintenance measures, the service life of the equipment can be extended, the processing quality can be improved, and production efficiency and safety can be ensured.