Four common difficulties and solutions in laser tube cutting

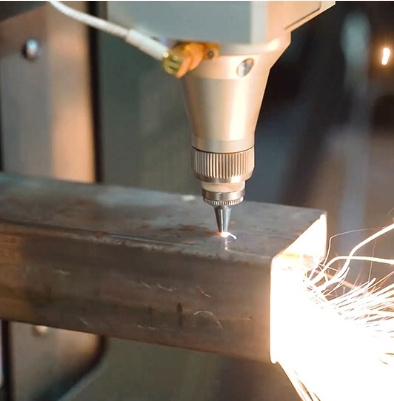

On the stage of modern industrial manufacturing, laser cutting technology has become a powerful assistant for many enterprises due to its advantages of high precision, high efficiency, and high flexibility. However, just like any advanced technology, laser Tube Cutting may also encounter some common problems in practical applications. But don't worry, we will analyze these issues one by one and provide practical solutions to make your laser cutting journey smoother.

1. Rough surface of cut pipe

Reason for occurrence:

1. Unstable laser power may be caused by laser aging, power failure, etc.

2. Improper cutting speed, too fast speed may cause incomplete melting of the pipe, while too slow speed may cause excessive melting.

3. Insufficient auxiliary gas pressure or purity, unable to effectively blow away the molten material.

4. The focusing lens is contaminated or damaged, which affects the focusing effect of the laser beam.

Resolvent:

1. Check the laser and power supply, repair or replace aging components in a timely manner, and ensure stable output of laser power.

2. By adjusting the appropriate cutting speed based on factors such as pipe material and thickness, the best cutting parameters can be found through multiple experiments.

3. Check the auxiliary gas supply system to ensure that the gas pressure is stable and the purity meets the requirements. If necessary, replace the gas supplier.

4. Regularly clean or replace the focusing lens to ensure the focusing quality of the laser beam.

2. Uneven width of pipe cutting seam

Reason for occurrence:

1. The laser beam is not focused accurately, which may be due to the position deviation or damage of the focusing lens.

2. The pipe is not firmly fixed and shakes during the cutting process.

3. The mechanical accuracy of the laser cutting machine decreases, such as rail wear and increased screw clearance.

Resolvent:

1. Check and adjust the position of the focusing lens to ensure accurate focusing of the laser beam. Replace it promptly if it is damaged.

2. Use appropriate fixtures to fix the pipes and ensure their stability during the cutting process.

3. Regularly maintain the laser cutting machine, inspect and adjust mechanical components, and replace worn guide rails, screws, etc.

3. Cutting accuracy does not meet the standard

Reason for occurrence:

The positioning accuracy of the laser cutting machine is insufficient, which may be caused by control system errors or mechanical structural deformation.

2. Thermal deformation of pipes, caused by the heat generated by laser cutting.

3. The drift of the laser beam may be due to the instability of the laser or external environmental interference.

Resolvent:

1. Upgrade the control system to improve positioning accuracy, while inspecting and repairing mechanical structural deformation issues.

2. Take cooling measures such as water spray cooling, air cooling, etc. to reduce the thermal deformation of pipes, optimize cutting process parameters, reduce laser power, and improve cutting speed.

3. Improve the stability of the laser, optimize the optical path design, and reduce the interference of external environment on the laser beam.

4. Pipe deformation

Reason for occurrence:

The high heat generated by laser cutting causes the local temperature of the pipe to be too high, leading to deformation.

2. The material of the pipe is relatively soft or thin, which is prone to deformation during the cutting process.

3. Unreasonable cutting process parameters, such as excessive laser power and slow cutting speed.

Resolvent:

1. Optimize cutting process parameters, reduce laser power, increase cutting speed, and reduce heat generation.

2. For pipes that are prone to deformation, appropriate support and fixing measures can be taken to increase the rigidity of the pipe.

3. Pre treat the pipe material before cutting, such as annealing, to improve its stability.

Summary

Laser cutting technology has shown significant advantages in the field of pipeline processing. Although it may encounter challenges in practical applications, by deeply understanding the root causes of these problems and implementing targeted solutions, we can still maximize the use of laser cutting technology to improve production efficiency and product quality. Choose Qiangang's high-quality laser cutting technology to help you achieve high efficiency, precision, and reliability in industrial production!